Celebrating 20 Years of Service Excellence

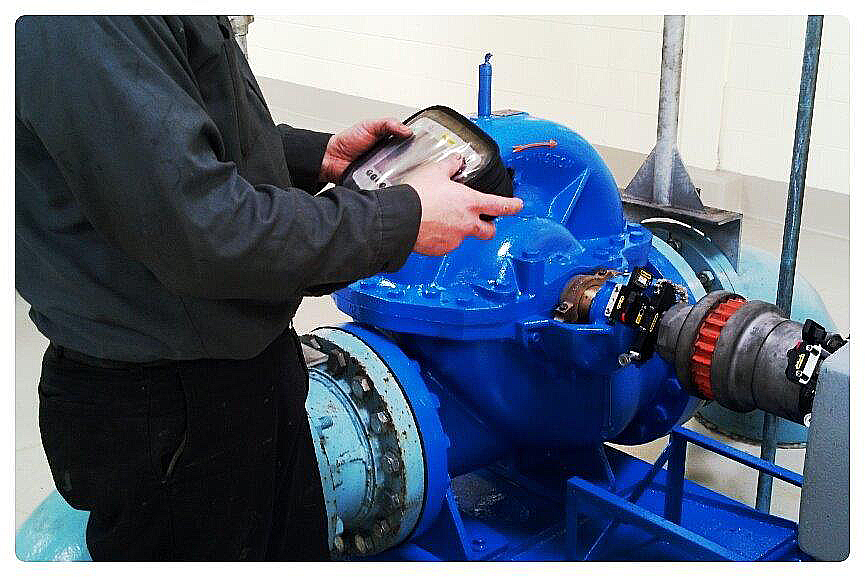

Shaft alignment is the positioning of the rotational centers of the shafts and should be co-linear and within the tolerated margin under normal operating conditions. Laser alignment measures this misalignment between two or more shafts. It is an absolute requirement for machinery to undergo laser alignment before being placed back into service.

Proper shaft alignment is not determined by the total indicator reading (TIR) of the coupling hubs or the shafts, but rather by the centers of rotation of the shaft supporting components, otherwise known as the bearings.

Excessive misalignment can generate forces directly to the bearings and cause excessive wear of the shaft seals. In extreme cases of misalignment, the bending stresses applied to the shaft will cause the shaft to fracture and break. Independent tests have shown that over 50% of the machine breakdowns that have occurred are a direct result of improper alignment.

Problems encountered as a result of improper alignment are:

APR offers Laser Alignment as a part of the field service package we can provide you with.

The benefits of having equipment laser aligned are:

In addition to this, proper alignment may also uncover problems such as: